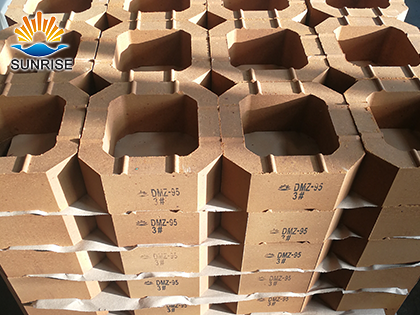

Fused Magnesia Brick Back

Back

- MgO Chemical composition: ≥95%

- Apparent Porosity: ≤18%

- Cold Crushing Strength: ≥55 Mpa

- 0.2Mpa Refractoriness Under Load T0.6: ≥1650

- Bulk Density: ≥2.95 g/cm3

- Thermal Stability 950℃ Wind cycles: ≥15

Features

Specifications

1.Fused Magnesia Brick Refractory

2.CCS:60mpa,RUL:1700

3.Good erosion resistance

4.High quality

5.Reasonable price

Fused Magnesia Brick Features:

Excellent performance of basic slag resistance, high refractoriness, thermal stability, anti-erosion and anti-peeling

Excellent strength of pressure bending, abrasion proof

Excellent performance of high-temperature firing, high rates of associative property, anti-erosion ability

Excellent thermal shock resistance and spalling resistance

Excellent ability of high refractoriness, anti-erosion of alkaline residue;

High temperature load of refractoriness under load. High mechanical strength

High temperature resistance excellent corrosion resistance

Resistance to spalling

The products are fused magnesia as main raw material, after a reasonable size distribution, high pressure forming, high-temperature sintering. The product has strong resistance to slag corrosion ability and high temperature dimensional stability. Mainly used in glass furnace regenerator, the upper part.

Application:

it is mainly applied to the regenerators of glass kilns and other high temperature glass furnaces.

Parameter

| Item | Behaviors | ||||

| Fused Magnesia Brick | |||||

| DMZ-95 | DMZ-96 | DMZ-97 | DMZ-98 | ||

| Chemical composition | MgO % | ≥95 | ≥96 | ≥97 | ≥97.5 |

| SiO2 % | ≤1.5 | ≤1.2 | ≤1.0 | ≤0.5 | |

| CaO % | ≤1.5 | ≤1.2 | ≤1.2 | ≤0.6 | |

| Apparent Porosity % | ≤18 | ≤18 | ≤17 | ≤15 | |

| Cold Crushing Strength Mpa | ≥55 | ≥60 | ≥60 | ≥60 | |

| 0.2Mpa Refractoriness Under Load T0.6 | ≥1650 | ≥1680 | ≥1700 | ≥1700 | |

| Bulk Density g/cm3 | ≥2.95 | ≥3.0 | ≥3.05 | ≥3.05 | |

| Thermal Stability 950℃ Wind cycles | ≥15 | ≥20 | ≥20 | ≥20 | |