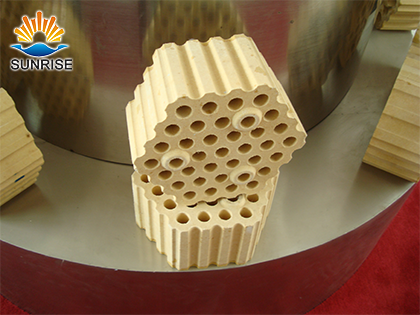

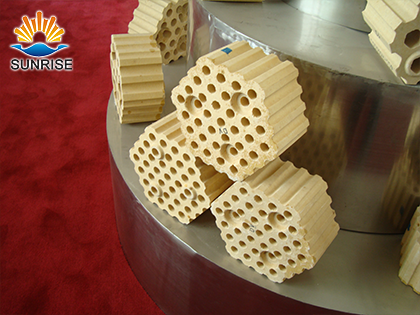

Silica brick for hot blast stove Back

Back

- Apparent porosity: ≤22(24)

- Cold crushing strength: ≥45(35)MPa

- 0.2MPa refractoriness under load: ≥1650(T 0.6,℃ )

- True density: 2.32g/cm3

- Thermal Expansion(1000℃): ≤1.25%

- :

Features

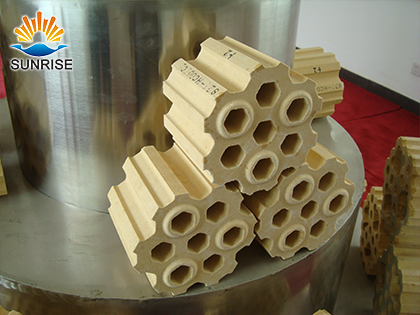

Silica bricks for hot blast stove for siliceous refractory products containing scaly quartz as the main phase in the high temperature part of the blast furnace hot blast stove.Due to the increase of wind temperature, the clay bricks or high alumina bricks used in the high temperature parts of the previous hot blast stoves are gradually replaced by silica bricks and low creep high alumina bricks.

The Advantages of Sunrise Silica Bricks for Hot Blast Stove:

High purity, good thermal conductivity, high refractoriness under load and high tridymite content, low true density, low expansion, low creep and low residual quartz content, good dimension and appearance.

Areas of Application:

Widely used in hot blast stoves, especially used in high temperature sections of the checker chamber in hot blast stoves.

As a professional refractory brick manufacturer, Sunrise company has a complete quality inspection standard and monitoring system. You can buy all kinds of high quality fire bricks here at a competitive price, so don’t be hesitate to contact us for free quotation.

Silica Brick for Hot Blast Stove Feature:

Hot air furnace silica brick has the following characteristics.

1.Under the condition of long-term high temperature and load, the volume is stable, the creep rate of high temperature is low, and one or even two blast furnaces can be used continuously;

2.Good thermal shock resistance above 600 degree C. Adapt to the variability of the hot blast stove temperature to keep bricks and masonry intact;

3.Chemical resistance is better than clay bricks and general high alumina bricks. The erosion of Silica bricks hot blast wood furnace by alkaline substances in gas and smoke is limited to the formation of a glass phase on the surface and does not peel off;

The thermal conductivity of silica bricks hot blast wood furnace is larger than that of clay bricks and high alumina bricks, which is beneficial for storing and releasing heat in a short time.

Silica Brick for Hot Blast Stove Products Requirement:

The shape of the product should be regular and the dimensional deviation should be small. The difference of the hole diameter of the check brick is ±1mm, and the Silica bricks hot blast wood furnace of other parts should not exceed ±1%. If the joint of the upper part of the external combustion type hot blast stove is made of composite brick, it needs to be cut before the masonry. Grind and pre-assemble. The surface crack width is not more than 0.5 mm and should have a length limit side. Cracks less than 0.1mm wide will not affect the use, there should be no cracks caused by improper cooling.

Silica Brick for Hot Blast Stove Using Requirement:

Hot air furnace silica bricks should be stored in a waterproof warehouse and can be used after being wetted at a temperature below 100 degree Celsius. Water-containing hot blast wood stove parts are affected by freezing and need to be re-inspected. The furnace should be set up to expand the expansion joint according to the thermal expansion rate provided by the manufacturer. The temperature rise curve of the oven should be reasonably formulated, especially in the more intense stage of expansion before 600 degree Celsius.

Parameter

|

|

RG-95 |

|

SiO2 ≥ |

95 |

|

Al2O3 ≤ |

1.0 |

|

Fe2O3 ≤ |

1.3 |

|

|

22(24) |

|

|

45(35) |

|

|

1650 |

|

|

2.32 |

|

|

1.0 |

|

|

0.8 |

|

|

1.25 |