BackNews

BackNews

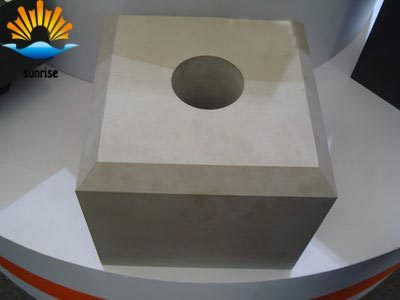

Brief analysis of hot-selling electric fusion and AZS brick

2019-12-25 16:15:51Electrofusion recombination AZS bricks are made by melting AZS clinker, scraps or recycled residual bricks (removing adhered glass) as raw materials, and adding a small amount of kaolinite or alumina as a binder. When heated to high temperature, the fused AZS aggregate exudates the glass phase and the binder forms mullite, which promotes the product to sinter. The peritectic reaction of the glass and crystal phases in the fused AZS aggregate will also form mullite.

At this time, the mullite and ZrO2 are wrapped and wrapped, which is helpful for sintering of AZS particles of different sizes. The "self-sinterability" of fused AZS aggregate is the basic principle for the production and recombination of AZS bricks.