BackNews

BackNews

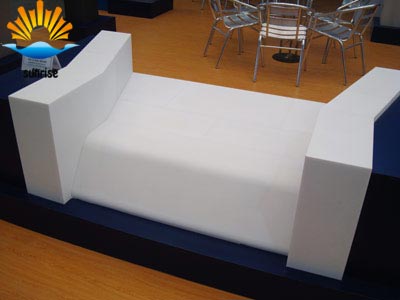

Sunrise Refractory Fused Cast Refractory Hot Sale all Over the World

2019-09-06 17:16:31Fused cast refractory is named by its manufacturing method. The term Fused Cast refers to a manufacturing process in which the ceramic bonding is obtained by the solidification of a mixture which has been melted in an electric furnace and cast in liquid state into molds.

Fused cast refractories usually have a lower apparent porosity (1-3%), a compression strength and a high deformation temperature. They have great corrosion resistance to melts such as glass and molten metal oxides due to compact structure and closed pores. They also offer the lowest blistering potential in many applications.

Fused cast refractories are manufactured by melting mixtures of raw material of the desired composition in an electric furnace at a temperature exceeding 2000°C, casting the melt into moulds where it solidifies and cooling the molten refractory material to form a solidified refractory. High density, small or large shapes are obtained. When appropriate, a finish is made by grinding with diamond tools.

Besides glass industry, Fused cast refractory materials are also used in many other industries such as iron & steel, aluminum, petrochemistry or wear resistant applications.

Our sunrise refractory company assures it's customers, the commitment for supply of undisputed quality big fire clay bottom blocks through it's modern facilities and experienced professionals through a philosophy of continual improvement. Our advantages also including about reliable quality, competitive price and prompt delivery, so that make our fused cast refractories popular both at home and abroad.

If you are interested in our fused cast refractories or have any question, please feel free to contact us for further information. We sincerely look forward to establishing a long-term mutually beneficial relations with all friends from around the world.