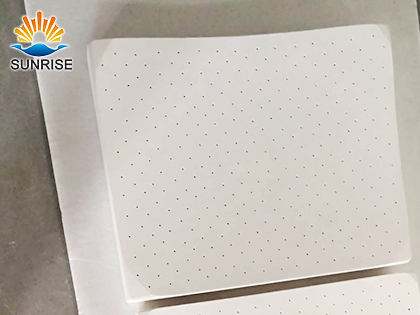

Glass Mould Brick Back

Back

- Cold Crushing Strength : ≥10 Mpa

- Cold Bending Strength : ≥1.5 Mpa

- Permanent Linear Change 1000℃X24h: ≤0.5 %

- Thermal conductivity 350±10℃: ≤0.35 W/m.k

- Bulk Density: ≥1.0 g/cm3

- Grain Size: ≤200 (mesh)

Features

With the development of the world automobile industry in recent years the technology on rearview mirror is also greatly improved, as demands a higher request on mold bricks in terms of its performance and quality. We have been working on the research and development. of Mold Bricks since 2000, and in March 2003 success was achieved in the trial manufacture, in Sep 2003 a Mold Brick production line was established, and we are now a factory specialized on Mold Brick for Viewing Mirrors.

MD Mold Bricks characterize as follows:

1. Low permanent linear change on reheating

Firing under the temperature of 1050 Degree. Ensures no distortion and no permanent linear change on the mold bricks.

2. High dense structure

MD Mold Brick is manufactured from micron grade material, which is pressed molding following being mixed by high speed blender. The maximum rod is 1000 with extremely fine section structure. 3. Good Thermal Shock Stability.

No cracks even chap would be happening after long service of the bricks

4. Easy to be machined

The Mold Brick is manufactured based on the customer request, which avoids waste from cutting of the big blocks.

We have established good fame among our customers since our mold brick line was put into production with some performances superior to similar products available in the market.

MD mold bricks could also be used in thermal bending glass, thermal melting glass and art glass. We sincerely welcome the comments from all our customers.

Parameter

MD Product Dimension List:

| No. | L(mm) | W(mm) | H(mm) |

| 1 | 450 | 250 | 25-150 |

| 2 | 450 | 320 | 25-150 |

| 3 | 300 | 300 | 25-150 |

| 4 | 380 | 300 | 25-150 |

| 5 | 510 | 270 | 25-150 |

| 6 | 510 | 510 | 25-150 |

| 7 | 440 | 360 | 25-150 |

| 8 | 600 | 480 | 25-150 |

| 9 | 500 | 380 | 25-150 |

Besides the specifications as listed above we meet your satisfaction based on customer requests, any problem don’t hesitate to contact us Physical and chemical index

| Item | Behaviors | |

| TY-MD | ||

| Typical Chemical Composition (%) | Al2O3 | ≥25 |

| Fe2O3 | ≤1.5 | |

| Cold Crushing Strength (Mpa) | ≥10 | |

| Cold Bending Strength (Mpa) | ≥1.5 | |

| Permanent Linear Change(%) 1000℃X24h | ≤0.5 | |

| Thermal conductivity 350±10℃ (W/m.k) | ≤0.35 | |

| Bulk Density (g/cm3) | ≥1.0 | |

| Grain Size (mesh) | ≤200 | |