Fused cast α-β Alumina Block TY-M Back

Back

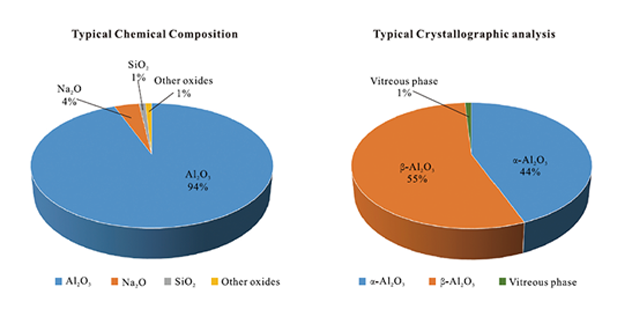

- Al2O3 Chemical Composition: 94%

- SiO2 Chemical Composition: 1%

- NaO2 Chemical Composition: 4%

- a-Al2O3 Crystallographic Analysis: 44%

- b-Al2O3 Crystallographic Analysis: 55%

- Vitreous Phase Crystallographic Analysis: 1%

Features

Fused cast Alumina Block TY-M Description

Fused cast Alumina Block TY-M is formed by the compact structure of α alumina and β alumina crystals in a most ideal proportion which is approximately 50% and 50% respectively,where intertwined crystals of both materials result in a very dense structure.TY-M has dense structure and no contamination to glass. It is the ideal refractory materials for channels, spouts and working ends of floating glass furnace.

Specifications and applications

--Below 1350 ℃, it has excellent corrosion resistance against molten glass and great performance against contamination to molten glass, thus it is very suitable for paving blocks and fore-hearth channel blocks.

--When in contact with molten glass, it barely produces any blistering or stones. So, α-β alumina blocks may be widely used in working tank, feeder channels, superstructures and lipstone, etc.

--In general, in soda-lime container furnaces α-β alumina fused-cast is installed in the Alcove and channel areas, as alternative to AZS fused-cast for Alcoves and as alternative to AZS fused-cast, zirmul, sinter-alumina and other sinter refractories for channels.

--In the float furnaces fused-cast α-β alumina is widely installed in the glass contact (sidewall and pavers) from the waist through the refining area up to spout and lip included.

Why us

We are engaged in offering excellent quality Fused Cast α-β Alumina Channel Block to our valuable clients. Fused α-β alumina are popularly used as distributor channel block and forehearths channel blocks because its strong resistance to glass corrosion and less pollution to glass quality. Clients can avail this Fused Cast α-β Alumina Channel Block at industry leading prices from us.

Parameter

| Item | FUSED CAST ALUMINA | |

| α-β Alumina TY-M | ||

| Chemical Composition % | Al2O3 | 94 |

| SiO2 | 1 | |

| NaO2 | 4 | |

| Other oxides | 1 | |

| Crystallographic Analysis % | α-Al2O3 | 44 |

| β-Al2O3 | 55 | |

| Vitreous Phase | 1 | |