Corundum Block Back

Back

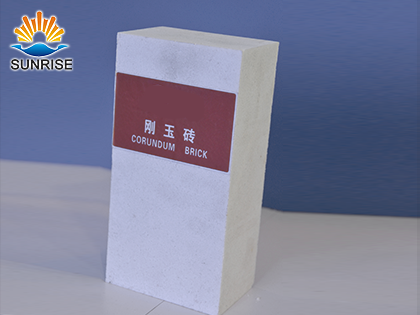

- Item : corundum block

- Apparent Prosity: ≤17%

- Bulk Density: ≥3.15 g/cm3

- Cold Crushing Strength: ≥100Mpa

- Refractoriness : ≥1900℃

- 0.2Mpa Refractoriness Under Load T0.6 ℃: ≥1700

Features

Main mineral component of corundum brick is corundum phase, it has excellent physical property in high temperature, resistance to chemical corrosion. It is widely used in lining of ovens of petrochemical industry; bottom of steel rolling mill and in the second-stage converters of the 300000t ammonia synthesis furnaces, steel notch.

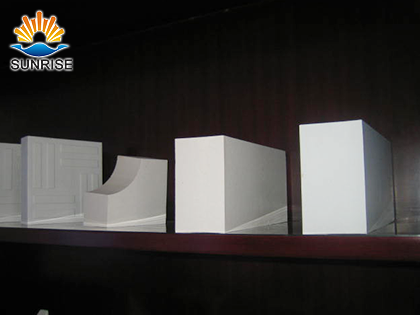

Application:

Fused corundum block is mainly used in key parts of the industrial furnace that require high abrasion and temperature resistance, such as gliding rail bricks in steel pusher metallurgical furnaces, the tapping platform (tapping spout) style walking beam furnaces, and also as the interior for destructors.

Parameter

| Item | Behaviors | ||

| TY-G93 | TY-G98 | ||

| Chemical Composition % | Al2O3 | ≥93 | ≥98.5 |

| SiO2 | ≤5.0 | ≤0.2 | |

| Fe2O3 | ≤0.1 | ≤0.1 | |

| CaO | ≤1.2 | ≤1.2 | |

| Na2O | - | - | |

| ZrO2 | - | - | |

| Cr2O3 | - | - | |

| Apparent Prosity (%) | ≤17 | ≤17 | |

| Bulk Density (g/cm3) | ≥3.15 | ≥3.2 | |

| Cold Crushing Strength ( Mpa) | ≥100 | 100 | |

| Modulus of Rupture at High Temperature 1250℃ (Mpa) |

≥9.5 | ≥9.5 | |

| Refractoriness (℃) | ≥1900 | ≥1850 | |

| 0.2Mpa Refractoriness Under Load T0.6 ℃ | ≥1700 | ≥1680 | |

| Reheat liner change 1600℃×3h (%) | ≤±0.2 | ≤±0.2 | |