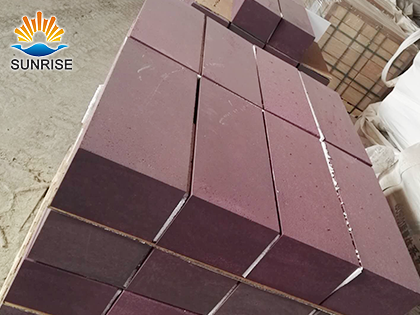

Chrome Corundum Block Back

Back

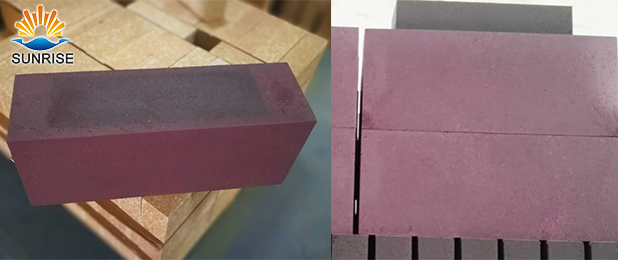

- Item : Fused chrome corundum block

- Apparent Prosity: ≤15%

- Bulk Density: ≥3.25 g/cm3

- Cold Crushing Strength: ≥180Mpa

- Refractoriness: ≥1900℃

- 0.2Mpa Refractoriness Under Load T0.6 ℃: ≥1680

Features

Fused chrome corundum block:

Due to its good chemical stability, high fire resistance, big intensity and good high temperature performance, it is a new top-grade refractory material with high erosion resistant. It is widely used for liner of high-temperature kilns required for steel, building material, non-ferrous smelt industry, light industry and chemical industry.

Application:

Fused chrome corundum block is mainly used in areas that require high abrasion and temperature resistance, such as gliding rail bricks in steel pusher metallurgical furnaces, the tapping platform (tapping spout) style walking beam furnaces, and also as the interior for destructors, In the linings of carbon soot furnace and copper smeling furnace tapping platform of rolling mill furnace, reheating furnace skid rail.

Parameter

| Item | Behaviors | |

| TY-G92-Cr | ||

| Chemical Composition (%) | Al2O3 | ≥92 |

| SiO2 | ≤1.0 | |

| Fe2O3 | ≤0.3 | |

| CaO | ≤1.2 | |

| Na2O | - | |

| ZrO2 | ≥3 | |

| Cr2O3 | ≥3 | |

| Apparent Prosity (%) | ≤15 | |

| Bulk Density (g/cm3) | ≥3.25 | |

| Cold Crushing Strength (Mpa) | ≥180 | |

| Modulus of Rupture at High Temperature 1250℃ (Mpa) |

≥9.5 | |

| Refractoriness (℃) | ≥1900 | |

| 0.2Mpa Refractoriness Under Load T0.6 (℃) | ≥1680 | |

| Reheat liner change 1600℃×3h (%) | ≤±0.2 | |